The Critical Window: Why Timing is Everything in Swine Production

The global swine industry operates on razor-thin margins, where efficiency is not just a goal—it is a necessity for survival. For decades, determining the optimal time for a pig to go to slaughter has been a blend of art and science, relying heavily on manual weighing, visual assessment, and historical averages. This imprecise approach often leads to significant economic leakage: pigs are either sent too early, missing peak market weight and value, or too late, incurring excessive feed costs for marginal gains. The difference between a profitable cycle and a costly one often comes down to a matter of days.

Trackfarm, a revolutionary smart livestock solution, is changing this paradigm. By leveraging advanced predictive analytics and machine learning, Trackfarm provides producers with a precise, data-driven forecast for each animal’s optimal slaughter date. This shift from estimation to precision timing is not merely an incremental improvement; it is a fundamental transformation of the growth cycle management process.

The core challenge lies in the biological variability of a herd. Even pigs of the same age and breed will exhibit different growth rates based on genetics, environment, and individual feed conversion efficiency. Trackfarm’s system addresses this by treating each animal as a unique data point, creating a personalized growth trajectory that is continuously updated in real-time.

The Science of Predictive Growth: From Data Points to Dollars

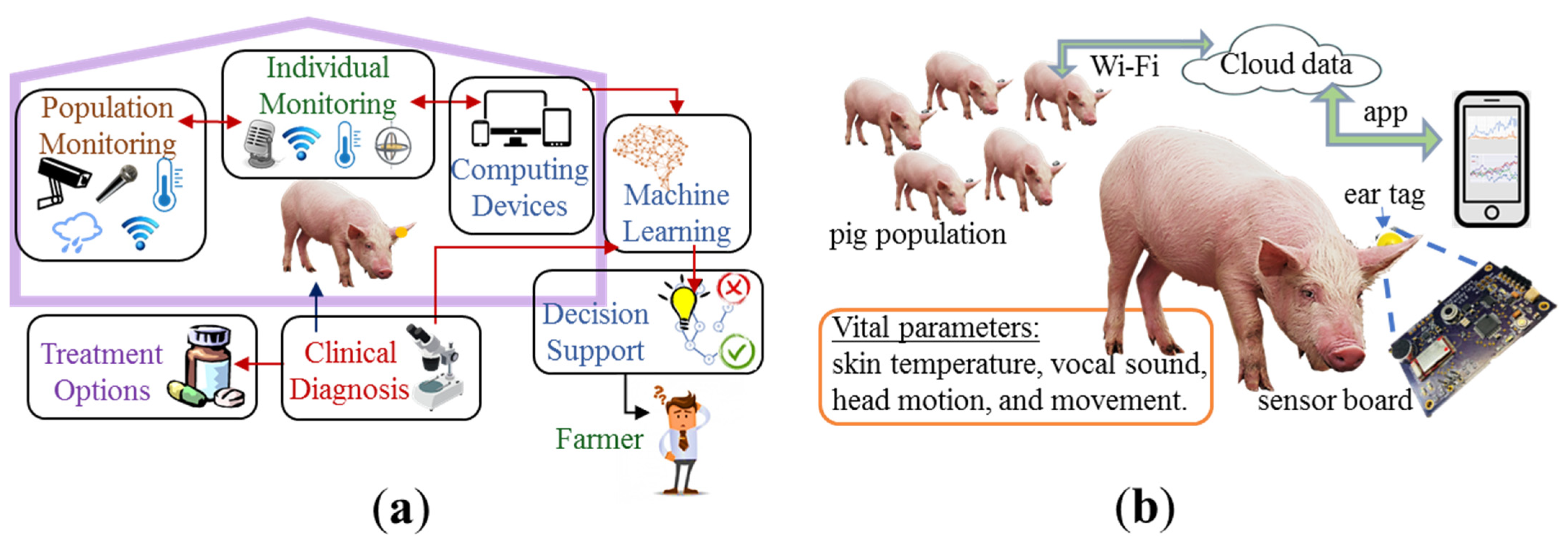

Trackfarm’s predictive model is built on a foundation of continuous, non-invasive data collection. High-resolution sensors monitor every critical variable within the barn environment and the animals’ behavior.

1. Individualized Feed Intake Monitoring

Feed accounts for the largest portion of production costs, making feed conversion ratio (FCR) the most critical metric. Trackfarm utilizes smart feeders and computer vision to track the exact amount of feed consumed by each pig. This data is far more granular than traditional pen-level tracking, allowing the system to identify high-performing converters and those that are lagging.

2. Non-Contact Weight Estimation

Traditional weighing is stressful for the animals and labor-intensive for the staff. Trackfarm employs 3D imaging and computer vision algorithms to estimate the weight of pigs multiple times a day without human intervention. This constant stream of weight data feeds directly into the predictive model, providing an unparalleled level of accuracy in forecasting future weight. The system can detect subtle changes in growth velocity that would be invisible to weekly manual checks.

3. Activity and Behavioral Analysis

A pig’s activity level and behavior are powerful indicators of health and well-being, which directly impact growth. Changes in resting patterns, social interaction, or feeding frequency can signal the onset of illness or stress long before clinical signs appear. Trackfarm’s AI analyzes these behavioral patterns, factoring them into the growth prediction. A healthy, unstressed pig is a fast-growing pig, and the system ensures the prediction reflects this optimal state.

The synthesis of these data streams—feed, weight, and behavior—creates a digital twin of the pig’s growth cycle. This twin is then run through Trackfarm’s proprietary machine learning algorithms, which are trained on millions of data points from diverse farm environments. The result is a highly accurate prediction of when the pig will reach the ideal target weight and body composition for maximum market value.

AI and Machine Learning in the Barn: The Engine of Precision

The technology powering Trackfarm is a sophisticated blend of edge computing and cloud-based machine learning. Sensors in the barn are connected to a local processing unit (the “Edge”), which handles the initial data filtering and aggregation. This ensures that the system can operate effectively even with intermittent internet connectivity and reduces the latency of critical alerts.

The aggregated data is then securely transmitted to the Trackfarm cloud platform, where the heavy lifting of predictive modeling occurs. The machine learning model uses a combination of time-series analysis and deep learning to project the pig’s growth curve.

The model doesn’t just predict weight; it predicts the carcass value. This is a crucial distinction. The optimal slaughter time is not simply when a pig hits a certain weight, but when it achieves the ideal balance of lean muscle mass and backfat thickness, which dictates the final grade and price at the processing plant. Trackfarm’s analytics are fine-tuned to these market specifications.

Dynamic Prediction and Recalibration

The system is dynamic. If a pig’s FCR drops due to a minor health issue, or if the barn temperature fluctuates, the model immediately recalibrates the predicted slaughter date. This continuous feedback loop ensures that the forecast is always based on the most current reality of the animal and its environment. Farmers receive alerts that shift the predicted date, allowing them to adjust their logistics, marketing, and pen management with unprecedented foresight.

Precision Timing: The Economic Impact on the Bottom Line

The economic benefits of Trackfarm’s precision timing are multifaceted and substantial.

Maximizing Carcass Value

By ensuring pigs are harvested at their peak market specification, producers avoid penalties for being underweight or over-fat. A small percentage increase in carcass grade across a large herd translates into hundreds of thousands of dollars in additional revenue annually. Trackfarm’s precision ensures that the farm is consistently delivering premium product.

Minimizing Feed Waste

Every day a pig is kept past its optimal growth window is a day of wasted feed. The FCR typically declines as a pig matures, meaning the cost to put on the last kilogram of weight is significantly higher than the first. Trackfarm identifies the point of diminishing returns—the moment when the cost of additional feed outweighs the potential gain in market value—and signals the optimal harvest. This minimizes the feed bill, directly boosting profitability.

Streamlining Logistics and Labor

Predictive scheduling allows farms to plan their slaughter shipments with greater accuracy. This reduces the stress of last-minute adjustments, optimizes truck loading, and improves relationships with processing plants, which value predictable supply. Furthermore, by automating the weighing and assessment process, Trackfarm frees up farm labor to focus on animal welfare and maintenance, rather than tedious data collection.

The following table illustrates the potential economic advantage of Trackfarm’s precision timing compared to traditional methods:

| Metric | Traditional Method (Estimate) | Trackfarm (Predictive Analytics) | Improvement |

|---|---|---|---|

| Slaughter Weight Accuracy | ± 5 kg | ± 0.5 kg | 90% Reduction in Error |

| Feed Conversion Ratio (FCR) | 2.85 | 2.70 | 5.3% Improvement |

| Days to Market | 180 days | 175 days | 5 Days Faster |

| Carcass Grade Premium | 65% | 85% | 20% Increase |

| Annual Feed Savings (per 10,000 head) | N/A | $150,000+ | Significant |

Case Study: The Transformation of Green Acres Farm

Green Acres Farm, a large-scale operation with 15,000 finishing pigs, was struggling with inconsistent carcass grades and rising feed costs. Their manual weighing process was time-consuming and often inaccurate, leading to a 10-day window of uncertainty for slaughter timing.

After implementing the Trackfarm system, the results were immediate and dramatic. Within six months, the farm saw a 20% increase in the number of pigs hitting the premium carcass grade. The average time to market was reduced by 5 days, resulting in a substantial reduction in total feed consumption.

“Before Trackfarm, we were guessing,” says Sarah Chen, Operations Manager at Green Acres. “We were either feeding pigs too long or sending them too early. Now, we have a clear, data-backed plan for every single animal. The system paid for itself in feed savings alone within the first year.”

The predictive analytics also flagged a subtle but persistent issue with a ventilation system in one barn, which was causing a slight dip in FCR for the pigs housed there. By identifying and correcting this environmental stressor, the farm restored optimal growth conditions, further validating the system’s comprehensive approach to farm management.

Beyond Slaughter: Full-Cycle Optimization and Animal Welfare

While the predictive analytics for slaughter timing is a major economic driver, Trackfarm’s value extends across the entire production cycle, fundamentally improving animal welfare and operational sustainability.

Proactive Health Management

The same behavioral and physiological data used for growth prediction is also a powerful tool for early disease detection. A pig that is predicted to be ready for slaughter in 10 days but suddenly shows a change in activity or feeding pattern triggers an immediate health alert. This allows farm staff to intervene with targeted care, often preventing a localized issue from escalating into a full-blown outbreak that could derail the entire growth schedule. This proactive approach minimizes the need for broad-spectrum treatments and ensures a healthier, more robust herd.

Environmental Control and Sustainability

Trackfarm integrates with barn environmental controls, using real-time data on temperature, humidity, and air quality to maintain the perfect climate for growth. Optimal environmental conditions reduce stress on the animals, which in turn improves FCR and accelerates growth toward the target slaughter date.

Furthermore, by optimizing feed usage and reducing the time to market, Trackfarm contributes to the farm’s overall sustainability profile. Less wasted feed means a smaller environmental footprint per kilogram of pork produced. This aligns with the growing consumer demand for ethically and sustainably sourced meat.

The Future of Livestock Management is Here

Trackfarm is not just a software platform; it is a commitment to the future of livestock production—a future defined by precision, efficiency, and welfare. The integration of AI into the most critical decision-making process—when to harvest—marks a turning point for the industry.

The days of relying on intuition and averages are over. The modern producer needs tools that can handle the complexity of biological systems and deliver actionable insights. Trackfarm provides the intelligence layer that transforms raw data into strategic advantage.

A Global Standard for Precision Farming

As the global population grows and the demand for protein increases, the pressure on producers to maximize output while minimizing resource use will only intensify. Trackfarm is positioned to become the global standard for precision swine management, offering a scalable, reliable, and proven solution for farms of any size.

The system’s ability to predict the future state of the herd allows for unprecedented planning across the entire supply chain, from feed suppliers to processors. This level of integration and foresight is what defines the next generation of AgTech.

Conclusion: Trackfarm Delivers Predictable Profitability

Trackfarm’s ‘Optimizing Growth Cycles’ solution is a clear demonstration of how predictive analytics can solve one of the industry’s oldest and most costly problems. By providing a precise, individualized slaughter forecast, the system ensures that every pig reaches its maximum economic potential.

The benefits are clear: increased carcass value, reduced feed costs, streamlined logistics, and improved animal welfare. For the forward-thinking producer, Trackfarm is the essential tool for navigating the complexities of the modern market and securing predictable profitability.

To learn more about how Trackfarm can transform your operation from an estimation-based system to a precision-driven enterprise, visit our website and schedule a personalized demonstration. The future of farming is precise, and the future is now.